Curing time. Solidification of crystalline bodies. How changes happen

Lesson topic: “Specific heat of fusion. Melting graphs and

solidification of crystalline bodies."

Lesson objectives:

Develop the ability to plot a graph of the temperature of a crystalline body depending on the heating time;

Introduce the concept of specific heat of fusion;

Enter a formula to calculate the amount of heat required to melt a crystalline body of mass m, taken at the melting temperature.

Develop the ability to compare, contrast, and generalize material.

Accuracy in drawing up schedules, hard work, the ability to complete the work started.

Epigraph to the lesson:

“Without a doubt, all our knowledge begins with experience.”

Kant (German philosopher 1724 – 1804)

“It’s not a shame not to know, it’s a shame not to learn”

(Russian folk proverb)

During the classes:

I. Organizing time. Setting the topic and goals of the lesson.

II. The main part of the lesson.

1. Updating knowledge:

There are 2 people at the board:

Fill in the missing words in the definition.

“The molecules in crystals are located..., they move..., held in certain places by the forces of molecular attraction. When bodies are heated, the average speed of movement of molecules ..., and the vibrations of molecules ..., the forces that hold them, ..., the substance passes from a solid to a liquid state, this process is called ... ".

“The molecules in a molten substance are located..., they move... and... are held in certain places by forces of molecular attraction. When a body cools, the average speed of movement of molecules ..., the range of vibrations ..., and the forces holding them ..., the substance passes from a liquid state to a solid, this process is called ... ".

The rest of the class works on mini-test cards ()

Using table values in the collection of Lukashik problems.

Option #1

1. Lead melts at a temperature of 327 0C. What can you say about the solidification temperature of lead?

A) It is equal to 327 0C.

B) It is higher than the temperature

melting.

2. At what temperature does mercury acquire a crystalline structure?

A) 4200C; B) - 390C;

3. In the ground at a depth of 100 km, the temperature is about 10,000C. Which metal: Zinc, tin or iron is there in an unmolten state.

A) zinc. B) Tin. B) Iron

4. The gas coming out of the nozzle of a jet aircraft has a temperature of 500 - 7000C. Can the nozzle be made from?

Can i. B) It is impossible.

Melting and solidification of crystalline bodies.

Option No. 2

1. When a crystalline substance melts, its temperature ...

B) decreases.

2. At what temperature can zinc be in a solid and liquid state?

A) 4200C; B) - 390C;

B) 1300 - 15000С; D) 00C; D) 3270C.

3. Which metal: zinc, tin or iron will melt at the melting temperature of copper?

A) zinc. B) Tin. B) Iron

4. The temperature of the outer surface of the rocket during flight rises to 1500 - 20000C. What metals are suitable for making the outer skin of rockets?

A) Steel. B). Osmium. B) Tungsten

D) Silver. D) Copper.

Melting and solidification of crystalline bodies.

Option No. 3

1. Aluminum hardens at a temperature of 6600C. What can you say about the melting point of aluminum?

A) It is equal to 660 0C.

B) It is below the melting point.

B) It is higher than the temperature

melting.

2. At what temperature does the crystalline structure of steel collapse?

A) 4200C; B) - 390C;

B) 1300 - 15000С; D) 00C; D) 3270C.

3. On the surface of the Moon at night the temperature drops to -1700C. Is it possible to measure this temperature with mercury and alcohol thermometers?

A) It’s impossible.

B) You can use an alcohol thermometer.

C) You can use a mercury thermometer.

D) You can use both mercury and alcohol thermometers.

4. Which metal, when in a molten state, can freeze water?

A) Steel. B) zinc. B) Tungsten.

D) Silver. D) Mercury.

Melting and solidification of crystalline bodies.

Option No. 4

1. During crystallization (solidification) of a molten substance, its temperature ...

A) will not change. B) increases.

B) decreases.

2. The lowest air temperature -88.30C was recorded in 1960 in Antarctica at the Vostok scientific station. What thermometer can be used in this place on Earth?

A) Mercury. B) Alcohol

C) You can use both mercury and alcohol thermometers.

D) Neither mercury nor alcohol thermometers should be used.

3. Is it possible to melt copper in an aluminum pan?

Can i. B) It is impossible.

4. Which metal has a crystal lattice that is destroyed at the highest temperature?

A) In steel. B) In copper. B) In tungsten.

D) Platinum D) Osmium.

2. Checking what is written at the board. Error correction.

3. Studying new material.

a) Film demonstration. "Melting and crystallization of a solid"

b) Constructing a graph of changes in the physical state of the body. (2 slide)

c) detailed analysis of the graph with analysis of each segment of the graph, study of all physical processes occurring in a particular interval of the graph. (3 slide)

melting?

A) 50 0С B) 1000С C) 6000С D) 12000С

0 3 6 9 min.

D) 16 min. D) 7 min.

Option No. 2 0C

segment AB? 1000

D) Hardening. B C

segment BV?

A) Heating. B) Cooling. B) Melting. 500

D) Hardening D

3. At what temperature did the process begin?

hardening?

A) 80 0C. B) 350 0С C) 3200С

D) 450 0С D) 1000 0С

4. How long did it take for the body to harden? 0 5 10 min.

A) 8 min. B) 4 min. B) 12 min.

D) 16 min. D) 7 min.

A) Increased. B) Decreased. B) Has not changed.

6. What process on the graph characterizes the VG segment?

A) Heating. B) Cooling. B) Melting. D) Hardening.

Graph of melting and solidification of crystalline solids.

Option No. 3 0C

1.Which process on the graph characterizes 600 G

segment AB?

A) Heating. B) Cooling. B) Melting.

D) Hardening. B C

2. What process on the graph characterizes

segment BV?

A) Heating. B) Cooling. B) Melting. 300

D) Hardening.

3. At what temperature did the process begin?

melting?

A) 80 0С B) 3500С C) 3200С D) 4500С

4. How long did it take for the body to melt? A

A) 8 min. B) 4 min. B) 12 min. 0 6 12 18 min.

D) 16 min. D) 7 min.

5. Did the temperature change during melting?

A) Increased. B) Decreased. B) Has not changed.

6. What process on the graph characterizes the VG segment?

A) Heating. B) Cooling. B) Melting. D) Hardening.

Graph of melting and solidification of crystalline solids.

Option No. 4 0C

1. Which process on the graph characterizes A

segment AB? 400

A) Heating. B) Cooling. B) Melting.

D) Hardening. B C

2. . What process on the graph characterizes

segment BV?

A) Heating. B) Cooling. B) Melting. 200

D) Hardening

3. At what temperature did the process begin?

hardening?

A) 80 0C. B) 350 0С C) 3200С D

D) 450 0С D) 1000 0С

4. How long did it take for the body to harden? 0 10 20 min.

A) 8 min. B) 4 min. B) 12 min.

D) 16 min. D) 7 min.

5. Did the temperature change during curing?

A) Increased. B) Decreased. B) Has not changed.

6. What process on the graph characterizes the VG segment?

A) Heating. B) Cooling. B) Melting. D) Hardening.

III. Lesson summary.

IV. Homework (Differentiated) 5 slide

V. Grading for the lesson.

To effectively plan all construction work, you need to know how long it takes for concrete to harden. And here there are a number of subtleties that largely determine the quality of the constructed structure. Below we will describe in detail how the solution is dried and what you need to pay attention to when organizing related operations.

To make the material reliable, it is important to properly organize its drying

Theory of polymerization of cement mortar

To manage the process, it is very important to understand exactly how it happens. That is why it is worth studying in advance what hardening of cement is (find out here how to make flowerpots from concrete).

In fact, this process is multi-stage. It includes both strength building and drying itself.

Let's look at these stages in more detail:

- Hardening of concrete and other cement-based mortars begins with the so-called setting. In this case, the substance in the formwork enters into a primary reaction with water, due to which it begins to acquire a certain structure and mechanical strength.

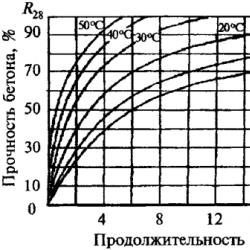

- Setting time depends on many factors. If we take the air temperature of 200C as a standard, then for the M200 solution the process starts approximately two hours after pouring and lasts about an hour and a half.

- After setting, the concrete hardens. Here the bulk of the cement granules react with water (for this reason the process is sometimes called cement hydration). Optimal conditions for hydration are air humidity of about 75% and temperature from 15 to 200C.

- At temperatures below 100C, there is a risk that the material will not reach its design strength, which is why special anti-frost additives must be used for work in winter.

Strengthening schedule

- The strength of the finished structure and the rate of hardening of the solution are interrelated. If the composition loses water too quickly, then not all the cement will have time to react, and pockets of low density will form inside the structure, which can become a source of cracks and other defects.

Note! Cutting reinforced concrete with diamond wheels after polymerization often clearly demonstrates the heterogeneous structure of slabs poured and dried in violation of technology.

Photo of a cut with clearly visible defects

- Ideally, the solution requires 28 days before complete hardening.. However, if the structure does not have too strict requirements for load-bearing capacity, then you can begin to operate it within three to four days after pouring.

When planning construction or repair work, it is important to correctly assess all the factors that will influence the rate of dehydration of the solution (read also the article “Non-autoclaved aerated concrete and its features”).

Experts highlight the following points:

Vibratory compaction process

- Firstly, environmental conditions play a crucial role. Depending on the temperature and humidity, the poured foundation can either dry out in just a few days (and then will not reach its design strength), or remain wet for more than a month.

- Secondly – packing density. The denser the material, the slower it loses moisture, which means that the hydration of cement occurs more efficiently. Vibration treatment is most often used for compaction, but when doing the work yourself, you can get by with bayoneting.

Advice! The denser the material, the more difficult it is to process after hardening. This is why structures that were constructed using vibration compaction most often require diamond drilling of holes in concrete: conventional drills wear out too quickly.

- The composition of the material also affects the speed of the process. Mainly, the rate of dehydration depends on the porosity of the filler: expanded clay and slag accumulate microscopic particles of moisture and release them much more slowly than sand or gravel.

- Also, to slow down drying and more effectively gain strength, moisture-retaining additives (bentonite, soap solutions, etc.) are widely used. Of course, the price of the structure increases, but you don’t need to worry about premature drying out.

Modifier for concrete

- In addition to all of the above, the instructions recommend paying attention to the formwork material. The porous walls of unedged boards draw a significant amount of liquid from the edge areas. Therefore, to ensure strength, it is better to use formwork made of metal panels or lay polyethylene film inside the wooden box.

Porous formwork actively “pulls” moisture from the material

Tips for organizing the process

Self-pouring of concrete foundations and floors must be carried out according to a certain algorithm.

To retain moisture in the thickness of the material and promote maximum strength gain, you need to act like this:

- To begin with, we perform high-quality waterproofing of the formwork. To do this, we cover the wooden walls with polyethylene or use special plastic collapsible panels.

- We introduce modifiers into the solution, the effect of which is aimed at reducing the rate of evaporation of the liquid. You can also use additives that allow the material to gain strength faster, but they are quite expensive, which is why they are used mainly in multi-story construction.

- Then pour the concrete, compacting it thoroughly. For this purpose, it is best to use a special vibrating tool. If there is no such device, we process the poured mass with a shovel or metal rod, removing air bubbles.

The less moisture leaves in the first days, the stronger the base will be.

- After setting, cover the surface of the solution with plastic wrap. This is done in order to reduce moisture loss in the first few days after installation.

Note! In autumn, polyethylene also protects cement located in the open air from precipitation, which erodes the surface layer.

- After about 7-10 days, the formwork can be dismantled. After dismantling, we carefully inspect the walls of the structure: if they are wet, then you can leave them open, but if they are dry, it is better to also cover them with polyethylene.

- After this, every two to three days we remove the film and inspect the concrete surface. If a large amount of dust, cracks or peeling of the material appears, we moisten the frozen solution with a hose and cover it again with polyethylene.

- On the twentieth day, remove the film and continue drying naturally.

- After 28 days have passed since the filling, the next stage of work can begin. At the same time, if we did everything correctly, the structure can be loaded “to its fullest” - its strength will be maximum!

Knowing how long it takes for a concrete foundation to harden, we will be able to properly organize all other construction work. However, this process cannot be accelerated, since cement acquires the necessary performance characteristics only when it hardens for a sufficient time (also find out how to build a concrete cellar).

More detailed information on this issue is presented in the video in this article.

To effectively plan all construction work, you need to know how long it takes for concrete to harden. And here there are a number of subtleties that largely determine the quality of the constructed structure. Below we will describe in detail how the solution is dried and what you need to pay attention to when organizing related operations.

Theory of polymerization of cement mortar

To manage the process, it is very important to understand exactly how it happens. That is why it is worth studying in advance what hardening of cement is ().

In fact, this process is multi-stage. It includes both strength building and drying itself.

Let's look at these stages in more detail:

- Hardening of concrete and other cement-based mortars begins with the so-called setting. In this case, the substance in the formwork enters into a primary reaction with water, due to which it begins to acquire a certain structure and mechanical strength.

- Setting time depends on many factors. If we take the air temperature of 20 0 C as a standard, then for the M200 solution the process starts approximately two hours after pouring and lasts about an hour and a half.

- After setting, the concrete hardens. Here the bulk of the cement granules react with water (for this reason the process is sometimes called cement hydration). Optimal conditions for hydration are air humidity of about 75% and temperature from 15 to 20 0 C.

- At temperatures below 10 0 C, there is a risk that the material will not reach its design strength, which is why special anti-frost additives must be used for work in winter.

- The strength of the finished structure and the rate of hardening of the solution are interrelated. If the composition loses water too quickly, then not all the cement will have time to react, and pockets of low density will form inside the structure, which can become a source of cracks and other defects.

Note! Cutting reinforced concrete with diamond wheels after polymerization often clearly demonstrates the heterogeneous structure of slabs poured and dried in violation of technology.

- Ideally, the solution requires 28 days before complete hardening.. However, if the structure does not have too strict requirements for load-bearing capacity, then you can begin to operate it within three to four days after pouring.

Factors affecting hardening

When planning construction or repair work, it is important to correctly assess all the factors that will influence the rate of dehydration of the solution ().

Experts highlight the following points:

- Firstly, environmental conditions play a crucial role. Depending on the temperature and humidity, the poured foundation can either dry out in just a few days (and then will not reach its design strength), or remain wet for more than a month.

- Secondly – packing density. The denser the material, the slower it loses moisture, which means that the hydration of cement occurs more efficiently. Vibration treatment is most often used for compaction, but when doing the work yourself, you can get by with bayoneting.

Advice! The denser the material, the more difficult it is to process after hardening. This is why structures that were constructed using vibration compaction most often require diamond drilling of holes in concrete: conventional drills wear out too quickly.

- The composition of the material also affects the speed of the process. Mainly, the rate of dehydration depends on the porosity of the filler: expanded clay and slag accumulate microscopic particles of moisture and release them much more slowly than sand or gravel.

- Also, to slow down drying and more effectively gain strength, moisture-retaining additives (bentonite, soap solutions, etc.) are widely used. Of course, the price of the structure increases, but you don’t need to worry about premature drying out.

- In addition to all of the above, the instructions recommend paying attention to the formwork material. The porous walls of unedged boards draw a significant amount of liquid from the edge areas. Therefore, to ensure strength, it is better to use formwork made of metal panels or lay polyethylene film inside the wooden box.

Self-pouring of concrete foundations and floors must be carried out according to a certain algorithm.

To retain moisture in the thickness of the material and promote maximum strength gain, you need to act like this:

- To begin with, we perform high-quality waterproofing of the formwork. To do this, we cover the wooden walls with polyethylene or use special plastic collapsible panels.

- We introduce modifiers into the solution, the effect of which is aimed at reducing the rate of evaporation of the liquid. You can also use additives that allow the material to gain strength faster, but they are quite expensive, which is why they are used mainly in multi-story construction.

- Then pour the concrete, compacting it thoroughly. For this purpose, it is best to use a special vibrating tool. If there is no such device, we process the poured mass with a shovel or metal rod, removing air bubbles.

- After setting, cover the surface of the solution with plastic wrap. This is done in order to reduce moisture loss in the first few days after installation.

Note! In autumn, polyethylene also protects cement located in the open air from precipitation, which erodes the surface layer.

- After about 7-10 days, the formwork can be dismantled. After dismantling, we carefully inspect the walls of the structure: if they are wet, then you can leave them open, but if they are dry, it is better to also cover them with polyethylene.

- After this, every two to three days we remove the film and inspect the concrete surface. If a large amount of dust, cracks or peeling of the material appears, we moisten the frozen solution with a hose and cover it again with polyethylene.

- On the twentieth day, remove the film and continue drying naturally.

- After 28 days have passed since the filling, the next stage of work can begin. At the same time, if we did everything correctly, the structure can be loaded “to its fullest” - its strength will be maximum!

Conclusion

Knowing how long it takes for a concrete foundation to harden, we will be able to properly organize all other construction work. However, this process cannot be accelerated, since cement acquires the necessary performance characteristics only when it hardens for a sufficient time ().

More detailed information on this issue is presented in the video in this article.

As the temperature decreases, a substance can change from a liquid to a solid state.

This process is called solidification or crystallization.

When a substance solidifies, the same amount of heat is released, which is absorbed when it melts.

The calculation formulas for the amount of heat during melting and crystallization are the same.

The melting and solidification temperatures of the same substance, if the pressure does not change, are the same.

Throughout the entire crystallization process, the temperature of the substance does not change, and it can simultaneously exist in both liquid and solid states.

LOOK AT THE BOOKSHELF

INTERESTING ABOUT CRYSTALLIZATION

Colored ice?

If you add a little paint or tea leaves to a plastic glass of water, stir and, having obtained a colored solution, wrap the glass on top and expose it to frost, then a layer of ice will begin to form from the bottom to the surface. However, don't expect to get colorful ice!

Where the water began to freeze, there will be an absolutely transparent layer of ice. Its upper part will be colored, and even stronger than the original solution. If the concentration of paint was very high, then a puddle of its solution may remain on the surface of the ice.

The fact is that transparent fresh ice forms in solutions of paint and salts, because... growing crystals displace any extraneous atoms and impurity molecules, trying to build an ideal lattice as long as possible. Only when the impurities have nowhere to go does the ice begin to incorporate them into its structure or leave them in the form of capsules with concentrated liquid. Therefore, sea ice is fresh, and even the dirtiest puddles are covered with transparent and clean ice.

At what temperature does water freeze?

Is it always at zero degrees?

But if you pour boiled water into an absolutely clean and dry glass and place it outside the window in the cold at a temperature of minus 2-5 degrees C, covering it with clean glass and protecting it from direct sunlight, then after a few hours the contents of the glass will cool below zero, but will remain liquid.

If you then open a glass and throw a piece of ice or snow or even just dust into the water, then literally before your eyes the water will instantly freeze, sprouting long crystals throughout the entire volume.

Why?

The transformation of a liquid into a crystal occurs primarily on impurities and inhomogeneities - dust particles, air bubbles, irregularities on the walls of the vessel. Pure water has no centers of crystallization, and it can become supercooled while remaining liquid. In this way it was possible to bring the water temperature to minus 70°C.

How does this happen in nature?

In late autumn, very clean rivers and streams begin to freeze from the bottom. Through the layer of clean water it is clearly visible that the algae and driftwood at the bottom are overgrown with a loose coat of ice. At some point, this bottom ice floats up, and the surface of the water instantly becomes bound by an ice crust.

The temperature of the upper layers of water is lower than the deep ones, and freezing seems to begin from the surface. However, clean water freezes reluctantly, and ice primarily forms where there is a suspension of silt and a hard surface - near the bottom.

Downstream from waterfalls and dam spillways, a spongy mass of inland ice often appears, growing in the foaming water. Rising to the surface, it sometimes clogs the entire riverbed, forming so-called jams, which can even dam the river.

Why is ice lighter than water?

Inside the ice there are many pores and spaces filled with air, but this is not the reason that can explain the fact that ice is lighter than water. Ice and without microscopic pores

still has a density less than that of water. It's all about the peculiarities of the internal structure of ice. In an ice crystal, water molecules are located at the nodes of the crystal lattice so that each has four “neighbors.”

Water, on the other hand, does not have a crystalline structure, and the molecules in the liquid are located closer together than in the crystal, i.e. water is denser than ice.

At first, when ice melts, the released molecules still retain the structure of the crystal lattice, and the density of water remains low, but gradually the crystal lattice is destroyed, and the density of water increases.

At a temperature of + 4°C, the density of water reaches a maximum, and then begins to decrease with increasing temperature due to an increase in the speed of thermal movement of molecules.

How does a puddle freeze?

As it cools, the upper layers of water become denser and sink down. Their place is taken by denser water. This mixing occurs until the water temperature drops to +4 degrees Celsius. At this temperature, the density of water is maximum.

With a further decrease in temperature, the upper layers of water can become more compressed, and gradually cooling to 0 degrees, the water begins to freeze.

In autumn, the air temperature at night and during the day is very different, so the ice freezes in layers.

The bottom surface of the ice on a freezing puddle is very similar to a cross section of a tree trunk:

concentric rings are visible. The width of the ice rings can be used to judge the weather. Usually the puddle begins to freeze from the edges, because... there is less depth there. The area of the resulting rings decreases as they approach the center.

INTERESTING

That in the pipes of the underground part of buildings, water often freezes not in frost, but in thaw!

This is due to poor thermal conductivity of the soil. Heat passes through the ground so slowly that the minimum temperature in the soil occurs later than at the surface of the earth. The deeper, the greater the delay. Often during frosts the soil does not have time to cool, and only when a thaw sets in on the ground does frost reach underground.

That when water freezes in a sealed bottle, it breaks it. What happens to a glass if you freeze water in it? When water freezes, it will expand not only upward, but also to the sides, and the glass will shrink. This will still lead to the destruction of the glass!

DID YOU KNOW

There is a known case when the contents of a well-chilled bottle of Narzan in the freezer, opened on a hot summer day, instantly turned into a piece of ice.

The metal “cast iron” behaves interestingly, which expands during crystallization. This allows it to be used as a material for the artistic casting of thin lace lattices and small tabletop sculptures. After all, when it hardens, expanding, cast iron fills everything, even the thinnest details of the mold.

In the Kuban in winter they prepare strong drinks - “vymorozki”. To do this, the wine is exposed to frost. The water freezes first, leaving a concentrated alcohol solution. It is drained and the operation is repeated until the desired strength is achieved. The higher the alcohol concentration, the lower the freezing point.

The largest hailstone recorded by humans fell in Kansas, USA. Its weight was almost 700 grams.

Oxygen in a gaseous state at a temperature of minus 183 degrees C turns into liquid, and at a temperature of minus 218.6 degrees C, solid oxygen is obtained from liquid

In the old days, people used ice to store food. Carl von Linde created the first home refrigerator, powered by a steam engine that pumped freon gas through pipes. Behind the refrigerator, the gas in the pipes condensed and turned into liquid. Inside the refrigerator, liquid freon evaporated and its temperature dropped sharply, cooling the refrigerator compartment. Only in 1923, Swedish inventors Balzen von Platen and Karl Muntens created the first electric refrigerator, in which freon turns from a liquid into a gas and takes heat from the air in the refrigerator.

THIS IS YES

Several pieces of dry ice thrown into burning gasoline extinguish the fire.

There is ice that would burn your fingers if you could touch it. It is obtained under very high pressure, at which water turns into a solid state at a temperature well above 0 degrees Celsius.

We present to your attention a video lesson on the topic “Melting and solidification of crystalline bodies. Melting and solidification schedule." Here we begin the study of a new broad topic: “Aggregative states of matter.” Here we will define the concept of a state of aggregation and consider examples of such bodies. And let's look at what the processes in which substances pass from one state of aggregation to another are called and what they are. Let us dwell in more detail on the processes of melting and crystallization of solids and draw up a temperature graph of such processes.

Topic: Aggregate states of matter

Lesson: Melting and solidification of crystalline bodies. Melting and solidification schedule

Amorphous bodies- bodies in which atoms and molecules are ordered in a certain way only near the area under consideration. This type of arrangement of particles is called short-range order.

Liquids- substances without an ordered structure of particle arrangement, molecules in liquids move more freely, and intermolecular forces are weaker than in solids. The most important property: they retain volume, easily change shape and, due to their fluidity properties, take the shape of the vessel in which they are located (Fig. 3).

Rice. 3. The liquid takes the shape of a flask ()

Gases- substances whose molecules interact weakly with each other and move chaotically, often colliding with each other. The most important property: they do not retain volume and shape and occupy the entire volume of the vessel in which they are located.

It is important to know and understand how transitions between states of matter occur. We depict a diagram of such transitions in Figure 4.

1 - melting;

2 - hardening (crystallization);

3 - vaporization: evaporation or boiling;

4 - condensation;

5 - sublimation (sublimation) - transition from a solid to a gaseous state, bypassing the liquid;

6 - desublimation - transition from a gaseous state to a solid state, bypassing the liquid state.

In today's lesson we will pay attention to processes such as melting and solidification of crystalline bodies. It is convenient to begin considering such processes using the example of the most common melting and crystallization of ice in nature.

If you place ice in a flask and start heating it with a burner (Fig. 5), you will notice that its temperature will begin to rise until it reaches the melting temperature (0 o C), then the melting process will begin, but at the same time the temperature of the ice will not increase, and only after the process of melting all the ice is completed, the temperature of the resulting water will begin to increase.

Rice. 5. Ice melting.

Definition.Melting- the process of transition from solid to liquid. This process occurs at a constant temperature.

The temperature at which a substance melts is called the melting point and is a measured value for many solids, and therefore a tabular value. For example, the melting point of ice is 0 o C, and the melting point of gold is 1100 o C.

The reverse process to melting - the process of crystallization - is also conveniently considered using the example of freezing water and turning it into ice. If you take a test tube with water and start cooling it, you will first observe a decrease in the temperature of the water until it reaches 0 o C, and then it freezes at a constant temperature (Fig. 6), and after complete freezing, further cooling of the formed ice.

Rice. 6. Freezing of water.

If the described processes are considered from the point of view of the internal energy of the body, then during melting all the energy received by the body is spent on destroying the crystal lattice and weakening intermolecular bonds, thus, energy is spent not on changing temperature, but on changing the structure of the substance and the interaction of its particles. During the process of crystallization, energy exchange occurs in the opposite direction: the body gives off heat to the environment, and its internal energy decreases, which leads to a decrease in the mobility of particles, an increase in the interaction between them and solidification of the body.

It is useful to be able to graphically depict the processes of melting and crystallization of a substance on a graph (Fig. 7).

The axes of the graph are: the abscissa axis is time, the ordinate axis is the temperature of the substance. As the substance under study, we will take ice at a negative temperature, i.e., ice that, upon receiving heat, will not immediately begin to melt, but will be heated to the melting temperature. Let us describe the areas on the graph that represent individual thermal processes:

Initial state - a: heating of ice to a melting point of 0 o C;

a - b: melting process at a constant temperature of 0 o C;

b - a point with a certain temperature: heating the water formed from ice to a certain temperature;

A point with a certain temperature - c: cooling of water to a freezing point of 0 o C;

c - d: the process of freezing water at a constant temperature of 0 o C;

d - final state: cooling of ice to a certain negative temperature.

Today we looked at various states of matter and paid attention to processes such as melting and crystallization. In the next lesson we will discuss the main characteristic of the process of melting and solidification of substances - the specific heat of fusion.

1. Gendenshtein L. E., Kaidalov A. B., Kozhevnikov V. B. /Ed. Orlova V. A., Roizena I. I. Physics 8. - M.: Mnemosyne.

2. Peryshkin A.V. Physics 8. - M.: Bustard, 2010.

3. Fadeeva A. A., Zasov A. V., Kiselev D. F. Physics 8. - M.: Education.

1. Dictionaries and encyclopedias on Academician ().

2. Course of lectures “Molecular physics and thermodynamics” ().

3. Regional collection of the Tver region ().

1. Page 31: questions No. 1-4; page 32: questions No. 1-3; page 33: exercises No. 1-5; page 34: questions No. 1-3. Peryshkin A.V. Physics 8. - M.: Bustard, 2010.

2. A piece of ice floats in a pan of water. Under what condition will it not melt?

3. During melting, the temperature of the crystalline body remains unchanged. What happens to the internal energy of the body?

4. Experienced gardeners, in the event of spring night frosts during the flowering of fruit trees, water the branches generously in the evening. Why does this significantly reduce the risk of losing future crops?